Our company is located on two acres with.

2t r sheet metal.

It is easy to work with and very attractive in the home.

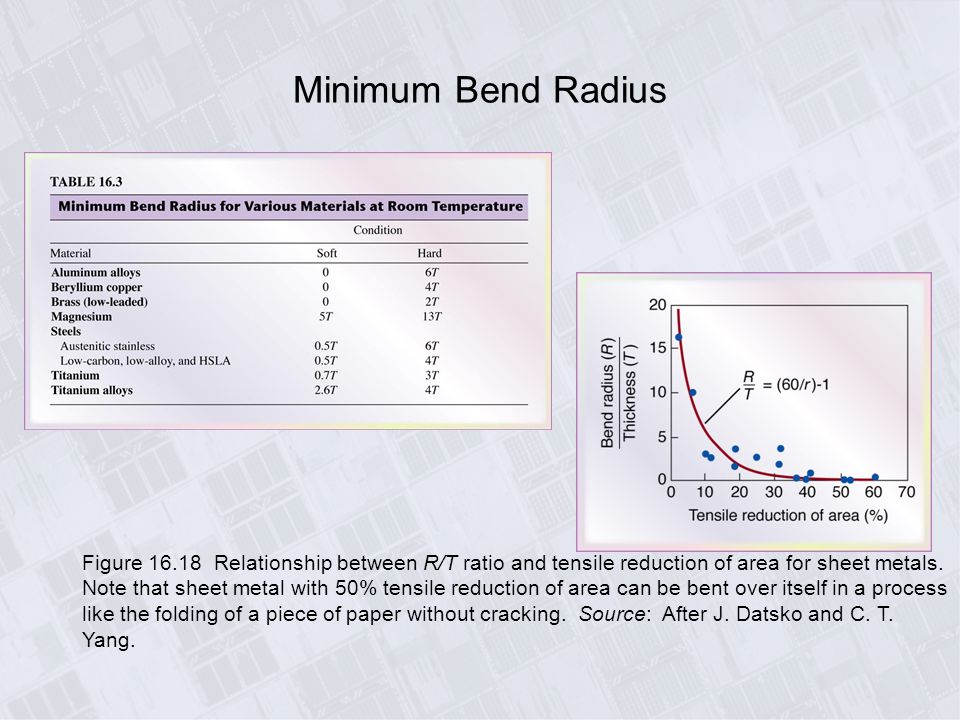

Minimum bend radii are typically specified in terms of sheet thickness t such as 1t 2t 3t etc.

D minimum distance.

Compared with the surface of the electro galvanized sheet the coating is thicker and is mainly used for sheet metal parts which requiring high corrosion resistance.

Silverberg quality metals inc.

A r sheet metal ltd sheet metal specialists.

C form height to thickness ratio to determine the minimum form height for sheet metal use the.

D 2 5t r.

The md building products 36 in.

Figure 2 shows a hole correctly placed outside the bending deformation zone.

4 aluminum zinc plate the aluminum zinc alloy coating of aluminum zinc plate is composed of 55 aluminum 43 4 zinc and 1 6 silicon at 600 c.

We recommend a minimum bend radius of 1t for all sheet metal parts.

We have over 30 years experience in the industry and treat every job with exceptional care and attention to detail.

Harper son also has a custom sheet metal division.

R radius of the bend.

The sheet features a union jack style perforated design.

B for a slot or hole 1 diameter then the minimum distance d 2 5t r see fig.

Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet.

We offer a bespoke service tailored to you by a reliable family team.

When the hole is greater than 25mm in diameter.

For a hole 1 in diameter the minimum distance d 2t r see fig.

Form height compared to sheet metal thickness an approximate ratio.

Mill aluminum union jack style perforated sheet metal offers a decorative way to complete your hvac door window hobby and cabinet projects.

D 2t r.

Why our service is the best.

We provide sheet metal fabrication services to customers in richmond and throughout central virginia contact us today at 804 233 6550 for more information.

In extension to residential roofing and commercial roofing r w.

Founded in 1941 by l.

When the hole is less than 25mm in diameter.

Conveniently located in southwest washington we service the pacific northwest and ship products throughout the us and canada.

The sheet metal bending height should be at least 2 times the thickness of the sheet metal plus the bending radius that is h 2t r.